Some Known Details About Cinder Block

Wiki Article

What Does Concrete Mixer Do?

Table of ContentsThe Basic Principles Of Stamped Concrete 10 Simple Techniques For Polished ConcreteThe 25-Second Trick For Cinder BlockUnknown Facts About Decorative ConcreteAn Unbiased View of Cement MixerCement Mixer Fundamentals ExplainedSome Known Incorrect Statements About Ready Mix Concrete

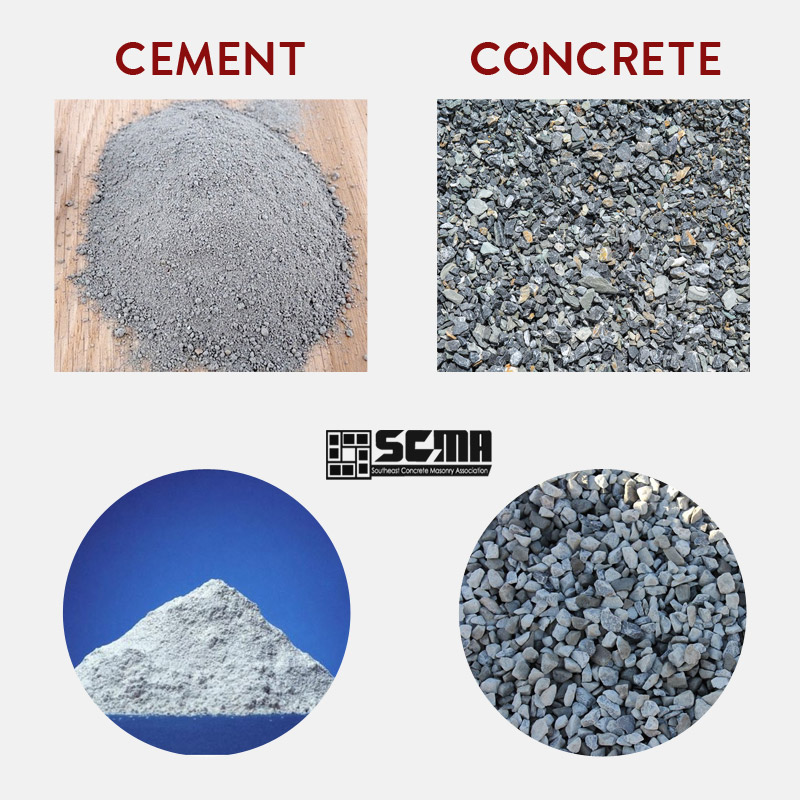

Cement is a powder made use of to make concrete (aon168/ Shutterstock). CEMENT VS. CONCRETE The words concrete and concrete are usually utilized mutually.

Type 1 is a basic use cement. - Is made use of for structures in water or soil consisting of modest amounts of sulfate, or when warm accumulation is a concern.

Concrete Fundamentals Explained

Used when high toughness are wanted at extremely early periods. - Low warmth rose city cement. Used where the amount and also rate of heat generation must be maintained to a minimum. - Sulfate immune portland cement. Made use of where the water or soil is high in alkali. Kinds IA, IIA as well as IIIA are cements made use of to make air-entrained concrete.Just ask them what their typical kind of cement is and also if that will work great for your conditions. WATER TO CONCRETE RATIO: THE # 1 CONCERN AFFECTING CONCRETE HIGH QUALITY A low is the leading problem impacting concrete high quality. The ratio is computed by dividing the water in one cubic backyard of the mix (in pounds) by the concrete in the in the mix (in pounds).

50 water to seal ratio. If the mix provides the water in gallons, increase the gallons by 8. 33 to find just how numerous extra pounds there are in the mix. Reduced water cement proportion impacts all the preferred residential properties of hardened concrete provided in desired residential properties of concrete. Use an optimum.

Excitement About Cement Mixer

(Table 19-A-2) Utilize an optimum. 45 water to seal proportion for concrete with serious or very severe sulfate problems per the 1997 Attire Structure Code (Table 19-A-4) Water permeability increases significantly when concrete has a water cement proportion more than. 50. Toughness boosts the less permeable the concrete mix is.

At Advanced, we sell mason sand by the lawn, bag or container Usual Inquiries concerning Masonry Sand What is Masonry Sand?, masonry sand is our second grade sand that is still very fine and soft to the touch. Many typical, mason sand is extremely concrete finishing flexible in it's features as well as can likewise be replaced for comparable uses to bank sand such as filling up a beach ball court or laying beneath a pool.

The smart Trick of Stamped Concrete That Nobody is Discussing

This procedure will eliminate all tiny rocks, stones and bits to guarantee that there is no damages to the devices you are utilizing from the sand. Bricklaying with Stonework Sand Why utilize stonework sand in your bricklaying? The function of stonework sand in your bricklaying project is to hold with each other your mortar mixture.With each other the sand and cement will certainly create a solitary substance that you can utilize in between bricks or stone blocks. When you are blending both with each other, a tip is to make sure that your mason sand is completely dry first. If it is wet, there is less of a possibility that the mortar mix will certainly stick together appropriately, resulting in breaking in the mortar.

The main reason that masonry sand varies from concrete sand is because mason sand goes with a procedure that concrete sand does not undergo. In this process, the mason sand is washed as well as evaluated. This permits the sand to not only be much more clean and also particle-free, yet it creates more uniform grains in the sand. polished concrete.

Getting My Ready Mix Concrete To Work

Concrete sand stays to have larger fragments in it such as rocks or pebbles and need to not be utilized for the same features as mason sand such as the base for a play area. Is Stonework Sand Safe for a Poultry Coop? Yes. When designing your poultry coop, there are several offered options for the floor covering.Considering that there are not big bits this page of sharp objects mixed in the sand, it is a comfy surface for the hen's feet. If you do choose to make use of sand, know the quantity of sun that is radiating on your hen coop, as well as make certain to frequently inspect the sand's temperature level.

* Wetting mason sand does not cause the sand hardening - concrete design. Leveling your Yard with Sand When you prepare to level out your lawn, ensure to begin by reducing your turf. Utilize your lawn mower to suffice down, not as well brief, and after that begin to dethatch it with a rake or dethatcher.

3 Simple Techniques For Cinder Block

As soon as dried out, it could take a day, re-add your dirt and also preserve care customarily.

An Unbiased View of Concrete Design

Negative aspects of Concrete(Blocks & Formwork )The building cost is much higher the price of concrete and mortar varies depending on the region and can price up a lot three times cost in some regions. Precast wall surfaces are made by pouring concrete right into types of defined measurements to make a whole wall surface in one piece. Concrete Stonework Units(CMU or precast concrete block wall )are commonly 8"X 8"X 16 "blocks that can be piled to develop wall surfaces.Report this wiki page